Power Plant Solution

I. Conceptual Design

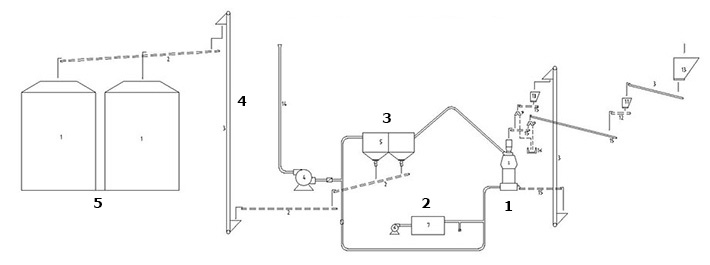

Pulverized Coal Production Process Plan Drawing

1. Vertical Roller Mill

2. Blast Furnace

3. Dust Collector

4. Elevating Conveyor

5. Pulverized Coal Bin

II. Required Equipment

Vertical Roller Mill

III. Solution Advantages

1. One single vertical roller mill consumes as little as 18-22 Kwh of electricity for each ton of pulverized coal produced. Wear-resistant parts of the mill ensure an extended use life. The mill is quite efficient at separating large coal particles from fine powder. It is able to produce narrower size distribution than is required under related standards.

2. A reasonable overall structure is a tangible guarantee of stable operation, ease use, and reliable control. This mill brings 30% electricity savings compared with a traditional ball mill. Its fuel economy reaches industry-leading standards.

3. High size-reduction ratio allows the mill to suitable for feedstock of HGI55~60 grindability. The mill is able to function properly under both high and low loads.

4. Noise control level meets the Emission Standard for Industrial Enterprises Noise at Boundary (GB12348-2008).

5. The average dust concentration in the surrounding atmosphere is lower than 1mg/m3, meeting the Emission Standard of Air Pollutants for Cement Industry (GB4915-2004).

Benefits

1. Pulverized coal is easier to burn than lumpy coal. It saves 30% of electricity, meeting the related national standards.

2. During grinding, the grinding roller does not contact directly with the grinding table. This grinding method reduces wear, extends parts use life, and saves production cost.

3. Normally speaking, the mill would produce 5 to 70 tons of powder coal in an hour. Percentage of coal particles larger than 80μm is as low as 3%.

Grinding Station Solution

I. Solution

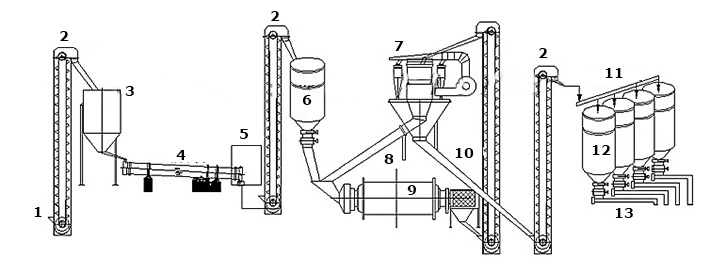

Grinding Process Design

1. Feedstock

2. Bucket Elevator

3. Silo

4. Baking Machine

5. Blast Furnace

6. Homogenizer

7. Separator

8. Coarse Material

9. Ball Mill

10. Fine Material

11. Screw Conveyor

12. Cement Silo

13. Screw Conveying Process

II. Required Equipment

Vertical Roller Mill for Cement

Vertical Roller Mill for Slag Powder

III. Solution Advantages

1. 30% Constructed Area Savings and 40%-50% Space Savings

Our vertical roller mill comes with a separator that uses hot air from the engine to transport the powder out of the mill and directly into the dust collector. This grinding method is rather simple, and hence the mill using this method can have a low failure rate, high production efficiency, and compact lay-out. It fits nicely in the small allotted space in your factory.

2. 80dB Noise Level

There is no direct contact between the grinding roller and rotating grinding table during grinding operation, This ensures minimum noise level that meets the Emission Standard for Industrial Enterprises Noise at Boundary (GB12348-2008). Generally speaking, our vertical roller mill maintains a noise level 20dB-25dB lower than an ordinary ball mill.

3. Dust Concentration Less than 1 mg/ m3

Our vertical roller mill a one-piece fully-sealed steel casting. It kicks up little dust under conditions of negative pressure. Its dust emission level meets the Emission Standard of Air Pollutants for Cement Industry.

4. Low Wear Rate

Traditional ball mill loses 500g of its parts for grinding each ton of cement clinker. Our vertical vertical roller mill, however, only wears down by 4-6g for the same amount of grinding task. This difference of wear rate between these two mills is mainly due to the fact that there is no direct contact, let alone collision, between metal parts in a vertical roller mill. Hence, the vertical roller mill is always a wise choice for it lasts longer, runs more steadily, and saves more production cost.

5. PC42.5 Cement with specific surface area of 3300~3800 cm2/g

Via adjusting the rotary speed of the separator, wind speed, and roller pressure, users can acquire powder of different finenesses. Even more convenient, powder finer than the required size can be moved out of the mill in time. This avoids over-grinding.

Benefits

1. On average, it only takes 1 to 3 years for a vertical roller mill to pay for itself.

2. The vertical roller mill uses the most advanced grinding techniques and process to bring users more than 30% power savings.

3. Taking into account all the money spent on initial construction, operation and maintenance, the vertical roller mill costs 20% to 30% less than a ball mill.

4. With our vertical roller mills, users can produce 55 to 250 tons of cement per hour. The resulting cement powder has a specific surface area of 3300~3800 cm2/g.

Steel Mill Solution

I. Solution

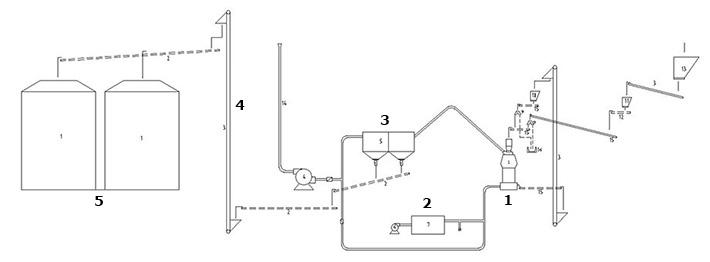

Slag Powder Production Process Plan Drawing

1.Vertical Roller Mill

2. Blast Furnace

3. Dust Collector

4. Elevating Conveyor

5. Slag Powder Silo

II. Equipment

Vertical Roller Mill for Slag Powder Vertical Roller Mill for Coal

III. Advantages

1. 20%~30% Electricity Savings (Compared to Ball Mill)

The vertical roller mill relies on the principle of multiple layers of materials grinding against one another. It uses little electricity to perform grinding operation. The more moisture the material contains, the more electricity savings the vertical roller mill will achieve.

2. Noise Control Meeting the Emission Standard for Industrial Enterprises Noise at Boundary (GB12348-2008)

In a ball mill, steel balls keeps colliding with each other as well as falling down on the liners, creating loud noise. This is contrasted with our vertical roller mill, which generally has a noise level 20dB-25dB lower than the ball mill.

3. Dust Concentration Less Than 1 mg/m3

Our vertical roller mill is a one-piece fully-sealed steel casting. It generates little dust when working at negative pressures. Its dust emission level meets the Emission Standard of Air Pollutants for Cement Industry (GB4915-2004).

4. 0.5%-1.0% Moisture Content in Finished Products

Hot air is used to transport finely ground particles out of the mill. Users can increase the inlet air temperature when handling materials that contain much moisture.

5. 5~10g/t Low Wear Rate

There is no direct contact between metal parts in a vertical roller mill. This results in low wear rate, long service lifetime and reduced production costs.

6. 4200~4500 cm2/g Specific Surface Area

Materials being ground only stay for a short time in the mill. It is easy to inspect and control the particle size and chemical composition. This reduces the need to re-grind large particles, ensuring users get consistently good-quality powder.

7. 50% Space Savings Compared to a Ball Mill

The vertical roller mill simplifies the grinding process with a simple, small-footprint structure. It can be placed outside your factory, thereby reducing the factory area requirements.

Benefits

1. It generally takes 1 to 3 years for a vertical roller mill to pay for itself.

2. Optimized grinding process and process control allow the mill to save 30%-50% electricity.

3. It takes less time to build a vertical roller mill related project. This results in time savings.

Mine Solution

I. Solution

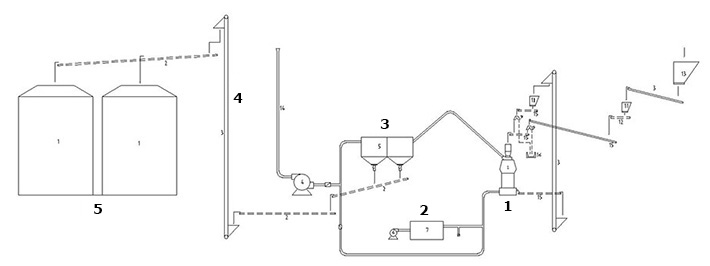

Vertical-Roller-Mill Involved Production Process Plan Drawing

1. Vertical Roller Mill

2. Blast Furnace

3. Dust Collector

4. Elevating Conveyor

5. Finished Product Bin

II. Equipment

Vertical Roller Mill Ball Mill

III. Advantages

1. Our vertical roller mill is very compact and takes up 50% to 60% less space than an ordinary ball mill. It can be placed outside the factory, thus reducing the factory construction cost.

2. The vertical roller mill saves 30%-40% electricity compared to a ball mill while generating 20dB lower noise and meeting the Emission Standard for Industrial Enterprises Noise at Boundary. (GB12348-2008)

3. Its one-piece, fully-sealed structure prevents dust from running out of the mill, maintaining a dust concentration lower than 1 mg/m³ in the surrounding atmosphere when working at negative pressures. Its dust emission level meets the Emission Standard of Air Pollutants for Cement Industry. (GB12348-2008)

4. Automatic control system allows users to easily control the mill from a distance. Regular inspection of the hydraulic cylinder as well as frequent replacement of roller coating and liner via turning the swing arm can reduce the risk of mill breakdown which might lead to heavy economic loss.

5. Materials being ground only stay for a short time in the mill. It is easy to inspect and control the particle size and chemical composition. This reduces the need to re-grind large particles, ensuring users get consistently good-quality powder.

Benefits

1. Advanced grinding process and techniques allow the mill to save more than 30% of electricity.

2. Taking into account all the money spent on initial construction, operation and maintenance, the vertical roller mill costs 20% to 30% less than a ball mill.

3. With our vertical roller mills, users can produce 70 to 720 tons of cement per hour. The percent of ground particles larger than 80μm falls between 12-15%.

Cement Plant Solution

I. Solution

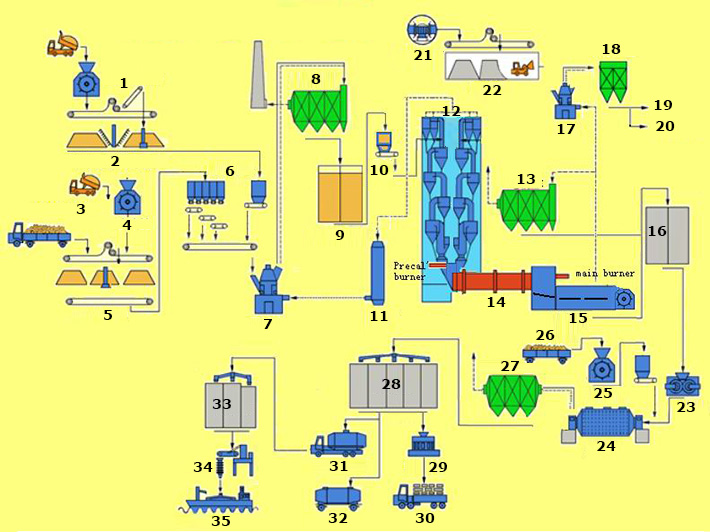

Cement Plant Process Plan Drawing

1. Limestone Crusher

2. Limestone Pre-Homogenization Yard

3. Cement Additive Entering the Factory

4. Crusher

5. Cement Additive Storage Yard

6. Batch Metering

7. Ball Mill for Cement Raw Material

8. Dust Collection

9. Cement Raw Material Homogenization Silo

10. Feedstock Metering

11. Humidifier Tower

12. Pre-heater

13. Electrostatic Precipitation

14. Rotary Kiln

15. Cooler

16. Cement Clinker Silo

17. Ball Mill for Coal

18. Coal Dust Collection

19. Going to the Rotary Kiln

20. Going to the Pre-Calciner

21. Raw Coal Entering the Factory

22. Coal Storage Yard

23. Vertical Roller Mill

24. Ball Mill for Cement Clinker

25. Crushing

26. Gypsum Entering the Factory

27. Cement Dust Collection

28. Cement Silo

29. Cement Packer

30. Bagged Cement Transported by Car

31. Bulk Cement Transported by Car

32. Bulk Cement Transported by Train

33. Silo at the Port

34. Ship-loader

35. Bulk Cement Transported by Ship

II. Equipment

Vertical Roller Mill for Slag

Vertical Roller Mill for Coal

Rotary Kiln

Vertical Roller Mill for Cement

III. Advantages

1. Worldwide Service and Mature Solution

As a global supplier of grinding system, Great Wall Machinery uses experience in product design, process control and energy efficiency management to provide customers from cement industry with high-quality, integrated cement grinding solutions. At Great Wall Machinery, not only is your cement production need satisfied, but your problems of cement project and project maintenance also get solved. Choosing us as your project manufacturer means you can focus more on your other core businesses in an effort to achieve your goal.

2. PC42.5 Cement with specific surface area of 3800cm²/g

Improvements in cement manufacturing process allow our vertical roller mill to produce fine powered cement that meets higher quality standards. The PC42.5 cement produced by our mill has a specific surface area up to 3800 cm²/g. Buying our vertical roller mill in place of a traditional ball mill means you are to produce finished goods that are reliable in your eyes.

3. 30% Energy Savings and 10% Improvements in Production Ability

Advanced process control and energy management methods allow our vertical roller mill to use 30% less electricity than an ordinary ball mill. For each ton of powdered cement produced, our mill consumes as little as 25-30kwh of electricity. Additionally, improvements in our production techniques enable us to improve the cement production ability of our mill by more than 10%.

4. Reduced Manual Labor and Enhanced Process Stability

No manual operation is needed during grinding process. Automatic control mode ensures high grinding stability, precision, and efficiency.

5. Dust Concentration Less than 1 mg/m³ and Noise Level around 80dB

Negative pressure system is utilized to reduce the chances of dust escaping outside the mill, resulting in dust concentration less than 1 mg/m³ in the surrounding atmosphere. Our vertical roller mill conforms to dust emission specifications listed in the Emission Standard of Air Pollutants for Cement Industry, and meets the noise control specifications required in the Emission Standard for Industrial Enterprises Noise at Boundary.

Benefits

1. It generally takes 1 to 3 years for your new production equipment to pay for itself.

2. With the new equipment, you can produce 55~250 tons of cement per hour.

3. 20% shortened deliver cycle means more time savings.

Русский

Русский Español

Español 中文

中文 العربية

العربية +8619838076183

+8619838076183