Production Facilities

FactoryToday, GREAT WALL Machinery is a half-century-old manufacturer with facilities stretching over 81 acres and more than 1100 employees. As a specialist in making large-scale rotary kiln, vertical roller mill and ball mill, we strictly adhere to ISO9001:2008 standards under which GREAT WALL Machinery is certified.

Large-Scale Assembly Workshop

We are capable of supplying a complete set of equipment that uses dry process to manufacture up to 10,000 tons of concrete per day. Main equipment involved in this process includes the vertical roller mill, rotary kiln, and ball mill.

Steel Casting Workshop- 9600㎡ Prototyping Workshop

- 23800㎡ Factory

- A Panoramic Photo of Factory

- Shot Peening Workshop

- Large-Scale Steel Castings

(made by using 4 casting ladles to pour molten steel into one mould)

- Grinding Table Support (made by using 4 casting ladles to pour molten steel into one mould)

- Natural Gas Station

- Oxygen Generator

Production Equipment

Large-Scale Machining Workshop

- CQ5250 Vertical Lathe (5m)

- CQ5250 Vertical Lathe (5m)

- The 3.15 vertical lathe is machining a hydraulic cylinder.

- CKJQ5280A Vertical Lathe (8m)

- CNC Controlled Cutter

- T6920A Milling Machine

- T6920A Milling Machine

- W250 Heavy-Duty Milling Machine Imported from Czech Republic

- W250 Heavy-Duty Milling Machine Imported from Czech Republic

- W250 Heavy-Duty Milling Machine Imported from Czech Republic

- W250 Heavy-Duty Milling Machine Imported from Czech Republic

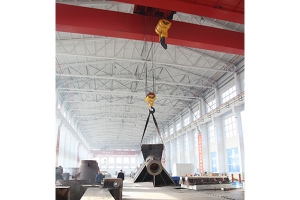

- Overhead Crane

- Overhead Crane

- Overhead Crane

- 7×12×4.5m Natural Gas Heat Treatment Furnace

- 2 sets of 20T Electric Arc Furnace

Inspection and Testing Equipment

GREAT WALL Machinery has introduced advanced, high-precision equipment to perform test and inspection on each and every machine we have made. The purpose of our inspection and test is to ensure the high quality of end products.

- German OBLF Direct Reading Spectrometer

- German OBLF Direct Reading Spectrometer

- Baking Equipment

- Elemental Analysis Equipment

- Carbon/Sulfur Analyzer

- Balance Scale

- Universal Testing Machine

- X-ray Flaw Detection

- Hammer Type Sample Maker

- Magnetic Particle Inspection Device

- Elemental Analysis and Experimenting

- Ultrasonic Flaw Detection for Drum

Русский

Русский Español

Español 中文

中文 العربية

العربية +8619838076183

+8619838076183