As the leading manufacturer of lime kiln, the CHAENG(Great Wall machinery) at home and abroad the same type of kiln absorbing and drawing on the "economic environment, high output efficiency" for the design concept, we developed a series of patented technology and non-standard kiln patent equipment, with perfect automatic control technology, energy efficient fully automated production, environmental discharge standards, the formation of domestic outstanding lime kiln technology. This type of rotary kiln with vertical preheater, vertical cooler with a high utilization of raw materials, firing a complete, uniform quality, good quality, large capacity, high rate of operation, energy saving, easy operation, automatic control, in line with the State Environmental Protection energy saving industrial policy, especially suitable for metallurgical, chemical and building materials industries calcined limestone.

1.create the perfect technology, leading the industry pioneer

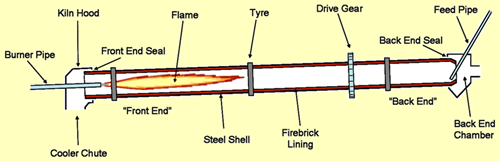

Lime kiln is a new type of environmental protection equipment, its primary drive system using the new AC frequency control technology, compared with traditional electromagnetic speed, DC speed, more energy-saving and environmental protection, and speed range, high efficiency, speed and high precision, running smoothly;

The use of advanced structure, low loss vertical preheater, can save 40% fuel indicators, production increased by 30% recycle exhaust heat, smoke conducive to dust, emission targets reached 30mg / m³.

For limestone calcination process characteristics and requirements of kiln, kiln segments for the overall structure optimization, to solve the same type of kiln kiln feed back and ubiquitous dust leakage, delivery more smoothly, naturally; for efficient use of energy, the use of the upper and lower furnace heat exchange, greatly reducing the limit from the upper and lower heat dissipation.

2. high-quality, high-yield, environmentally friendly energy

Environmentally friendly energy mix burnt lime kiln, the kiln to achieve three-stage thermal process the preheating zone, firing zone, equitable distribution of the cooling zone, the fuel energy to make full use, the material from the preheater at the top of the silo by cutting slide tubing into the preheater body, while the high temperature flue gas from the kiln pass the material preheated to above 1000 ℃, so that partial decomposition of limestone, then followed by the hydraulic push rod is pushed into the tail of the rotary kiln, the rotary kiln calcination then unloaded into a cooler, cold air blown by the cooling fan, the material was cooled to ambient temperature below 60 ℃ + cooler discharge. Cooler air is blown through the air into the rotary kiln as secondary combustion participation. In the course of all operations are closed and automated flue gas discharged from the pipeline and reach through the dust pollution emissions. Both to achieve high-quality high-yield, but also to achieve energy saving and environmental protection.

3. matching dust removal equipment, for you to create a green project

Kiln combustion flue gas temperature after the preheater and limestone for heat exchange, the temperature dropped to below 250 ℃, and then carried into a cyclone dust collector collecting the dust collecting large particles, then after entering the baghouse dust into the atmosphere at high temperature fan, exhaust gas dust concentration of less than 30mg / m³, fully meet the modern environmental requirements. In the import filter is also provided with cold air control system for dust protection.

CHAENG provide High activity lime kiln calcination better ,configuration flexible, configurable vertical preheater kiln in full use within a rotary kiln to produce high temperature flue gas, preheat the limestone from room temperature to the initial state of decomposition, You can also configure vertical cooler at high temperature in a kiln lime quench, improve the degree of activity, but also easy to transport and storage.

Русский

Русский Español

Español 中文

中文 العربية

العربية +8619838076183

+8619838076183